Compressed air

The compressed air is the second largest dynamic energy only after the electric power in factories, and which is also a multi-purpose process air source. The utilization of compressed air is quite mature due to the reliable and stable air source provided by it and its excellent features and elasticity in conveyance and storage. Furthermore, the air source is easy to operate, so it is widely used in the industry.

Clean compressed air shall meet the following requirements:

- The liquid moisture inside the piping shall be removed completely and the gaseous moisture as much as possible the dew-point temperature below 10°C;

- The amount of oil mist residues shall be kept between 0.8~1.0ppm and the dust and carbon ash particles over 0.3~1.0μ m shall be removed;

- The compressed air adopted for painting, the dust over 0.01μm shall be removed and the amount of oil mist residues shall be 0.01ppm;

- The compressed air adopted for respirator, food and medical industries, the dust over 0.01μ m and peculiar smell shall be removed, and the amount of oil mist residues shall be 0.003ppm.

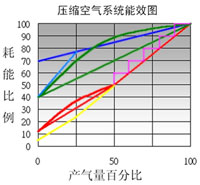

THE SYSTEM OF ENERGY SAVING

Because of the compressed air is secondary energy, there will beenergy consumption when the electric power is converted into the compressed air and only 10%~15% efficiency is used on the terminal unit. Therefore, it is relativelyexpensive comparing with the electric power.According to the Project Research on the U.S.A. Motor System Energy Saving, the compressed air system accounts for 20%~30% in motor power consumption of the factory averagely. Based on the data of BEKO Company, as for the 110kw air compressor that operates 7,500 hours yearly, 86% cost is spent on the consumption of electric power, and only 10% on the purchase of it and 4% on maintenance. So how to improve the efficiency of it is quite influential to its operation cost on production.

power.According to the Project Research on the U.S.A. Motor System Energy Saving, the compressed air system accounts for 20%~30% in motor power consumption of the factory averagely. Based on the data of BEKO Company, as for the 110kw air compressor that operates 7,500 hours yearly, 86% cost is spent on the consumption of electric power, and only 10% on the purchase of it and 4% on maintenance. So how to improve the efficiency of it is quite influential to its operation cost on production.

The applied air pressure of the common air compressor is 7bar and each motor outputs about 125L compressed air/minute, so about 10% power will be consumed for increasing 1bar of the pressure of the compressed air system and 1% of the system efficiency will be improved for decreasing every 5°C of the inlet temperature. According to the Project Research on the U.S.A. Motor System Energy Saving, the leakage amount of most compressed air systems is 20%~30%, but it shall be less than 10% under normal conditions. The volume of air holder is about 1/5~1/2 of the air displacement per minute of the air compressor. The air compressor system shall consume about 80%~90% electric power for the idle air temperature rise, and 90% of it can be recycled.

With 20% of the system leakage as an example

E.g.: if a 30HP (22kw) air compressor operates 7,500 hours yearly with an average electric charge of RMB 0.8/kwh, the extra loss caused by leakage is RMB26,400 yearly. 22kw × 20% × 7,500hr/year × RMB0.8/kwh =MB26,400/year.

EU's experience in promoting the energy saving of compressed air system shows that there is a space for most factories to improve. As for the improvement measures,50% of them are to improve the leakage situation, 10% to decrease the pressure, 30% for system control, air production equipment and heat recovery with each accounting 10%, and the rest for other individual improvement measures.Therefore, it shows that there is a small space for the air compressor to improve its energy saving in the aspect of realization of energy saving of the compressed air system, except there is a greater technological change (taking a long time) on the whole system, and nearly 70% improvements depend the optimization of the piping of compressed air.

ENERGY SAVING OF AIR COMPRESSOR EQUIPMENT

How enhances the air compressor equipment the operating efficiency, to saves the electrical energy and reduces the production cost to have the count for much significance.

The first issue is how to select a cabinet which can meet the demands and can operate with high efficiency after installed from various air compressors.Before deciding the type and dimensions of the air compressor, it is a must to confirm firstly: system air consumption amount, quality of compressed air and working pressure, and collect the corresponding statistic data, calculate the actual demand for the compressed air in a short-term and increased demand amount of the future capacity expansion and consider 10%-20% surplus.After completing the above evaluation, reference the cabinet parameters provided by the air compressor manufacturer to allocate corresponding cabinet reasonably.The operation cost of the air compressor is very high. The cost of electric power consumed by the air compressor that operates more than 4000 hours yearly is enough to buy more than one new air compressor, so special attentions shall be paid on its operating efficiency. All supporting enterprises and users must realize the wrong ideas about the configuration of air compressor, and choose the products with China Energy Label and good reputation except selecting a reasonable type of the air compressor; as long as the purchase cost does not exceed over two times of that of the product of same category, the energy-saving air compressor is more advantageous over the medium to long term.

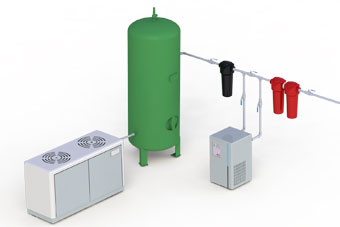

Air compressor equipment Energy saving of the air compressor equipment takes a long time and needs process supervision. Beside of the original efficiency determined by the properties of air compressor, it shall lay stress on the interlock control of several air compressors, air storage tank, air dryer and filter, and reasonable connection of each equipment, and it should focus even more on the long-term supervision of the air temperature humidity, air intake resistance and cleanliness, etc.

ENERGY SAVING OF COMPRESSED AIR PIPING

ENERGY SAVING OF COMPRESSED AIR PIPING

The clean compressed air produced from the compressed air station must be conveyed from the piping to pneumatic equipment on site. If the design and installation of the piping is not qualified, the following problems will occur:

- Increased pressure-drop and insufficient air flow

- Air re-pollution

- Not able to discharge condensation water

- Undesirable use of pneumatic equipment and unstable product quality

- Difficult to maintain and overhaul

| PROPERTIES OF MATERIALS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LOW PRESSURE-DROP In the compressed air piping, the increase of pressure drop will cause the rise of the air compressor's output pressure, and the electric power consumption amount will rise by about 8%-10% for each 1bar rise of the air compressor's output pressure.Therefore, it is a must to adopt corrosion resistant pipes with low roughness of pipe inside wall, low pressure-drop and a large enough pipe diameter at the very beginning (not use unnecessary pipe fittings as much as possible but adopt largeradian elbow and bend), full bore valve with a simple structure, various connecting parts and quick couplings of a large flow rather than blindly increasing the pressure output of the air compressor. When the compressed air is passing through the pipe, fitting or valves, the friction between liquid molecular and the pipe inside wall will emergence pressure-drop,which is proportional to the flow, pipe length, roughness of pipe inner wall, amount of condensation water in the air, pipe fittings and valves etc. With the standarddesigned pipe diameter, when the flow increases by one time, the on-way resistance (pressure drop) emergence from the pipe will be four times of the original value; or when the pipe diameter decreases by one half, the on-way resistance (pressure drop) will be 39.7 times of the original value. Thereby, the pipe diameter needed in the future must be accurately predicted in the beginning, because it is difficult to change the main pipe as it is fixed.There is local resistance (pressure drop) on the pipe fitting, valve and connecting parts, etc. When the elbow, coupling and valve in the compressed air piping increased, the pressure-drop will increase also. Furthermore, the opening degree of the valve is different and the difference of local resistance is also big, so all valves shall be kept completely open or close. |

EXCELLENT MATCHING

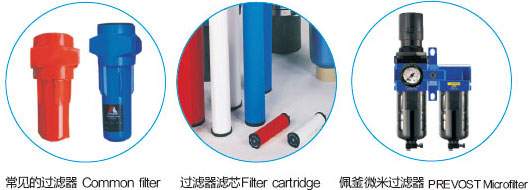

FILTER

FILTER

In the compressed air piping, there are two devices which will greatly influence the compressed air transporting efficiency, namely the filter which will cause the pressure-drop to raise obviously, the quick coupling that will cause the pressuredrop to rise obviously and a large amount of leakage.

A common filter filters air through a fine screen mesh. And because of this structure, the screen mesh will surely be blocked due to a long time use and the local resistance of air passing will increase, which directly cause the pressure-drop to rise dramatically when the air passing through it. To handle with this issue, attentions shall be paid on the installation of all types of filters inside the pipeline at the very beginning. The unnecessary filters shall not be installed but the necessary filters cartridge must be cleaned or changed regularly. An excellent filter cartridge will surely provide air with idea quality and reduce the comprehensive cost of use and maintenance.

QUICK COUPLING

QUICK COUPLING

The quick coupling with one-way valve will cause pressure-drop in the compressed air piping. As the fluid passes through the internal valve, the internal valve is like the stone in the river which will cause "instability" in the fluid and then cause the loss of the pressure intensity. So, the design, materials and precision of the valve assembly are the basic standards to judge the pressure drop level of the quick coupling, and the wear resistant function and sealing function of the adapter and bell end material are also related to the leakage level of the fluid and the service life of the coupling etc.

There are a lot of supply terminal on a compressed air piping and each supply terminal requires a quick coupling mostly, so hundreds or thousands of quick couplings need not only excellent quality, but also long-term strict supervision and maintenance.